Universal Fit Catalysts

← For individual product information and to order use the search function…

Jetex offer a huge range of high flow, performance catalysts that are designed to reduce back pressure and increase engine power output through significantly increased exhaust gas flow over OEM and standard aftermarket converters. This is achieved by a using a lower density stainless steel monolith matrix: 100 or 200 cells per square inch (cpsi), when compared to a standard ceramic substrate (400 or 600 cpsi). Stainless steel monoliths withstand extreme vibration and temperatures that normally would destroy standard ceramic substrates. The result is a more durable and longer lasting converter. Our catalysts can be supplied as complete units for welding (or clamping – depending on the type of catalyst) or as components for the customer to create their own catalyst. For off-road or track use we recommend a 100 cell catalyst. Some cars are used for both and therefore sometimes a 200 cell is necessary. For road cars we recommend a 200 cell catalyst for emissions compliance (for cars up to March 1st 2001).

Please note that is is illegal to fit a non-type approved catalyst (universal catalyst) to a road-going vehicle first used on or after 01/03/2001, as per The Motor Vehicles (Replacement of Catalytic Converters and Pollution Control Devices) Regulations 2009.

How to choose the right catalyst

Understanding which catalyst to use requires a few questions to be answered to narrow your choice down. There are different cell structures, mantle sizes, end cones, pipe diameters, BHP and emission ratings to deal with. But, it isn’t complicated. Once you know what your application requires, the catalyst will do the hard work.

Off road/track use? (usually use 100 cell)

Most track meets whether FiA or non-FiA require that a catalyst of some sort is fitted. As road emissions regulations are not an issue, a 100 cell catalyst can be used. For FiA championships, an FiA approved 100 cell catalyst has to be used; an example can be seen here. All FiA converters are supplied as complete working units and ready to be welded to pipework. 100 cell catalysts are the least restrictive and ensure track compliance. If the vehicle is to be used on the road, a 200 cell catalyst is necessary.

Or road use? (usually use 200 cell)

Since 1992 all production cars in the UK had to have a catalyst fitted. Then in 2001, all catalysts had to be EC approved. This was to ensure that catalysts did the job they were intended for. Alongside this, the allowable amount of CO2, NOX, CO and HCs emitted by petrol engines has been reduced through EC emissions rules. We are currently on Euro 6 standard with Euro 7 due around 2025:

- Euro 1 – 12/1992-12/1996

- Euro 2 – 01/1997-12/2000

- Euro 3 – 01/2001-12/2005 (for this standard an EU approved catalyst must be fitted)

- Euro 4 – 01/2006-12/2010 (for this standard an EU approved catalyst must be fitted)

- Euro 5 – 01/2011-08/2015 (for this standard an EU approved catalyst must be fitted)

- Euro 6 – 09/2015+ (for this standard an EU approved catalyst must be fitted)

- (Euro 7 – 2025+)

For these standards to be achieved with high flow converters (only for cars up to March 1st 2001 – after this an EU approved catalyst must be fitted), a 200 cell is a minimum requirement. Below are some examples of how low emissions can be achieved.

Example 1 – Saab 93 310bhp 2006

Catalyst Fitted: 5″ diameter Euro 5 (a Euro level higher than required)

- Emissions before:

CO – 0.563 %vol

HC – 106 ppm

Lambda – 1.111

- Emissions after with Jetex catalyst:

CO – 0.01 %vol – ↓ 98.2%↓

HC – 4 ppm – ↓96.2%↓

Lambda – 1.005

Example 2 – Range Rover Evoque 2017

Catalyst Fitted: 5″ diameter Euro 5

- Emissions with Jetex catalyst (Fast Idle):

CO (max. 0.2%) – Reading 0.00% PASS

HC (max. 200ppm) – Reading 10ppm PASS

Lambda (Range 0.97-1.03) – Reading 1.02 PASS

Example 3 – BMW X7 V8 2020 (with existing pre-cats in place)

Catalyst Fitted: 5″ diameter Euro 5

- Emissions with Jetex catalyst (Fast Idle):

CO (max. 0.2%) – Reading 0.04% PASS

HC (max. 200ppm) – Reading 31ppm PASS

Lambda (Range 0.97-1.03) – Reading 1.00 PASS

Which diameter?

There are 3 different diameter converters available; 4″, 4.5″ and 5″. Each has a different gas flow capacity and which size depends on the BHP output of the engine. Generally it is always advisable to fit the biggest possible. This ensures minimal increase in back pressure and also, by fitting a larger converter, the surface area is greater and so the gas will have more chance to come out cleaner at the other end. Our general guidance to BHP v catalyst diameter is as follows:

- 4″ up to 170bhp for non-turbo or 255bhp for turbo engines

- 4.5″ up to 215bhp for non-turbo or 325bhp for turbo engines

- 5″ up to 250bhp for non-turbo or 375bhp for turbo engines

These recommendations are more towards ensuring emissions are attained with 200 cell converters. With 100 cell the ratings are not so critical.

Complete unit or as parts?

FiA, Euro 3/4 (e-marked) and Euro 5 catalyst options are all complete converter units, ready to be welded into an existing exhaust system. These save time, have lambda fitting points and are rated according to specific emissions/regulations.

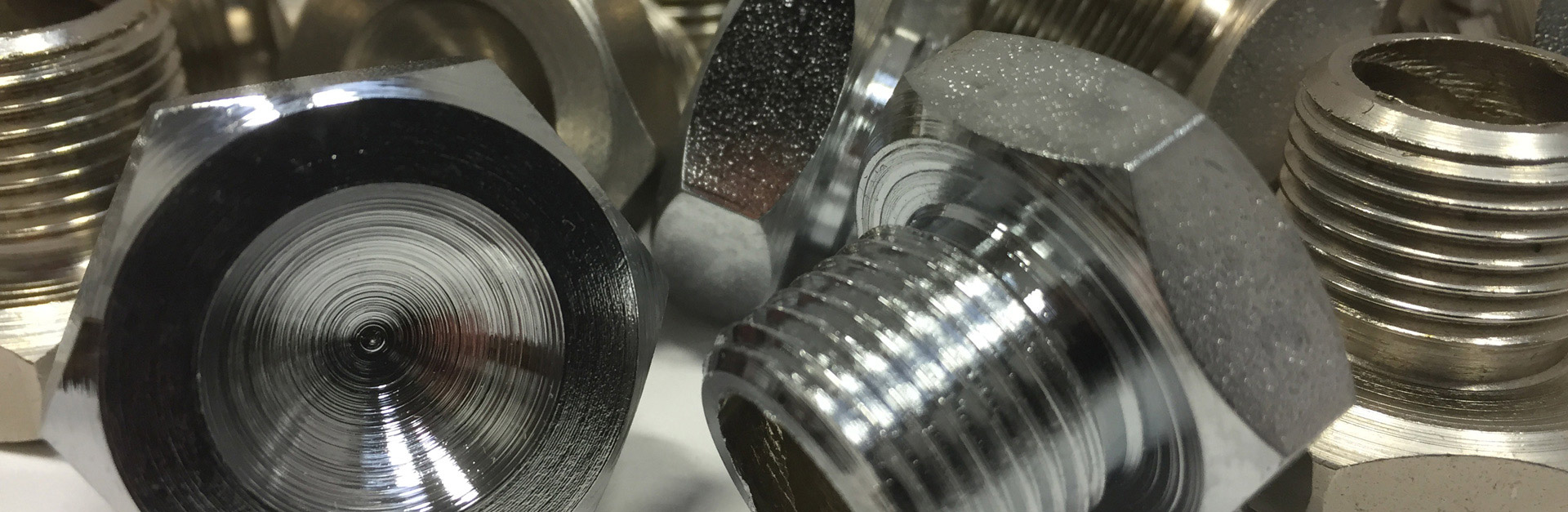

Another option is to make up your own catalyst using the mantels, cones and end stubs on their own. While the parts need to be welded together, there is an option of buying specific end connectors which allow the converter unit to be clamped in place. We always recommend converters to be welded in place, but slip joints do allow the easy removal of a catalyst.

There are a variety of different diameters to suit a large range of pipe sizes. These converter parts are generally suited for Euro 2/3 standards. To choose the right ‘DIY’ converter, follow these steps:

- Choose a mantle diameter

- Choose the right cone to weld to the mantle

- Choose the right end connector depending on your existing pipe diameter

Use this link and use the drop down menu to choose the correct parts for steps 1 (mantels), 2 (cones) and 3 (end stubs/connectors). Some more info is shown below:

Converters for Self-Assembly

Mantles

We have 100 or 200 cpsi mantles (diameters of 4″, 4.5″ and 5″) that should be used in conjunction with our welding cones and stubs. Cones butt up to the mantle and can be TIG or MIG welded. Stubs should be used if the converter is to be clamped, but we recommend the converters are welded in place.

Cones

Designed to be welded to 4″, 4.5″ and 5″ mantles. If used without stubs/connectors, the cones must be welded to the existing exhaust system.

Connectors/Sleeves

To be used in conjunction with 4″, 4.5″ and 5″ cones. Available to fit pipe diameters from 45mm to 76mm (1.75″ to 3″).

High Flow DPFs

Suitable as a replacement for an OEM DPF, our high flow DPFs increase gas flow, resulting in reduced back pressure of up to 50%, while maintaining a near parity in particulate extraction (80%) when compared to a standard DPF.

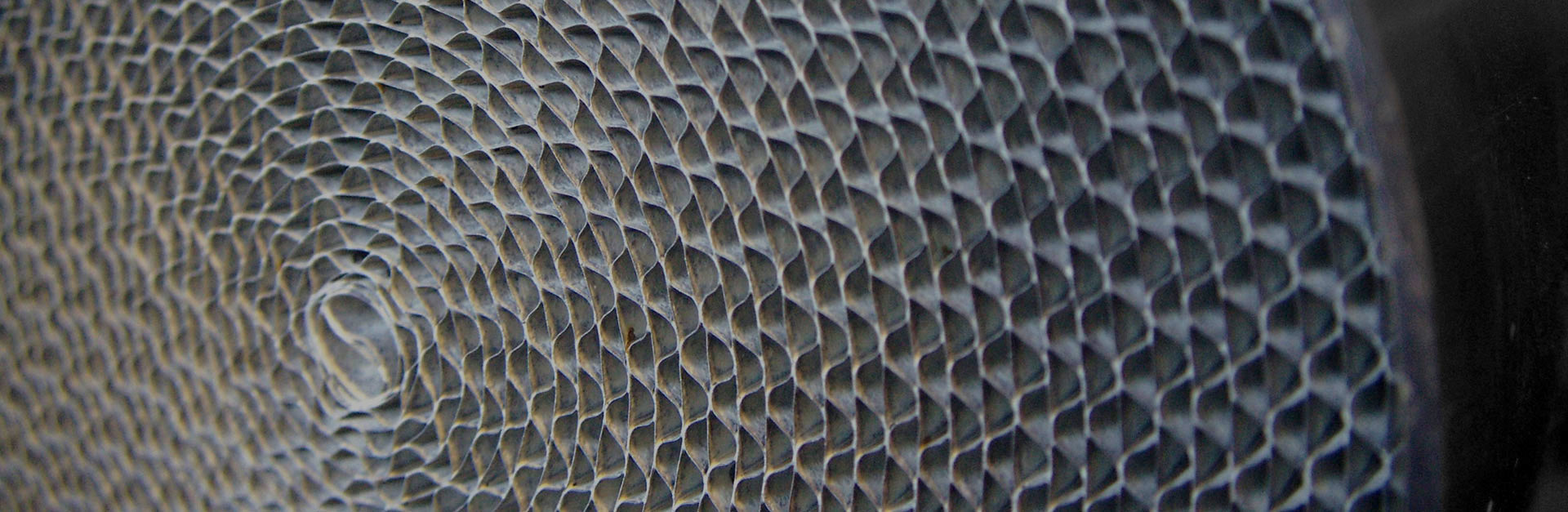

The unique dimpled spiral core combined with active surface molecules react with the exhaust gas when the DPF reaches 300 degrees. The particles are burnt off and so the DPF works continually, unlike a standard DPF which collects the particles and then has to enter regeneration mode, leading to loss of performance and inconvenience.

Suitable for Motorsport and Road Applications.

For 2″ (50.8mm) to 3″ (76mm) pipework.

Please note that is is illegal to fit a non-type approved UNIVERSAL DPF to a road-going vehicle first used on or after 01/03/2001, as per The Motor Vehicles (Replacement of Catalytic Converters and Pollution Control Devices) Regulations 2009.

|

|

Comments are closed.